Commercial Slab on Grade Design Essentials

When designing a commercial slab on grade, we balance cost and quality by carefully considering key factors such as slab thickness, reinforcing materials, and concrete mix proportioning to minimize cracking and guarantee durability. For heavy loads, we guarantee adequate thickness, reinforcing, and soil bearing capacity. Proper material selection and controlled water content further enhance slab quality. We also integrate effective drainage and waterproofing systems and pay close attention to site preparation and finishing, mixing, placement, and curing processes. By understanding these essentials, our slabs will stand the test of time; we'll explore each of these critical aspects in detail.

Key Takeaways

- Thickness and strength of the slab are crucial for load-carrying capabilities and minimizing cracking.

- Proper material selection and proportioning, such as welded wire reinforcement, enhance slab durability.

- Effective drainage and waterproofing are essential for slab longevity and safety by preventing water accumulation around foundations.

- Soil compaction and proper subslab preparation ensure even slab support and prevent settlement.

Concrete Design Considerations

When designing concrete slabs on grade, we must carefully consider several key factors, including the overall slab thickness, reinforcing materials, and the proportioning of the concrete mix. These elements all play a meaningful role in ensuring the slab can efficiently handle load distribution and withstand various types of loading over its lifespan. It is essential to balance the need for a thick enough slab to resist cracking and the economic constraints of minimizing costs. Adequate reinforcing is vital to help mitigate the risks of cracking, particularly with thermal expansion and contraction.

Moreover, we must enhance the concrete mix to achieve the desired strength and durability while maintaining ideal workability during construction. This can be achieved through strategic control of water content within the mix, as excessive water can lead to issues such as shrinkage cracking. The incorporation of beneficial additives like entrained air and correctly selecting the proportion of different aggregate sizes can also contribute considerably to the overall quality of the slab. By meticulously addressing these concrete design considerations, we can engineer a durable and reliable slab on grade that effectively meets the performance needs of commercial buildings.

Strength and Materials

The thickness and strength of a commercial slab on grade are vital design parameters that must be carefully managed to guarantee ideal load-carrying capabilities and minimal cracking risks. We recognize that load considerations are essential in this process, particularly when dealing with heavy foot traffic and the constant use of forklifts in industrial settings. The selection of the right materials is also key to achieving the desired strength and durability.

Load considerations are a primary driver in the design of commercial slabs. For instance, if the slab will support heavy racking systems, the thickness and modulus of subgrade reaction must be increased to handle the added load. Industry standards guide us in determining the required slab thickness based on the clear height of the building. For example, a 40-foot clear height generally necessitates an 8-inch slab thickness.

A robust material selection process must also be in place. This includes using the appropriate reinforcement, such as welded wire reinforcement (WWR), which helps mitigate cracking and improves the overall durability of the slab. Additionally, we need to manage the water-to-cement ratio in the mix design to guarantee a strong and stable concrete. By correctly balancing these factors, we can create a slab that meets the needs of the end user.

Structural Integrity

We must guarantee that our slab on grade design incorporates key structural integrity factors like slab thickness, shear strength, and deflection control to prevent damage and collapse. Making certain the correct structural integrity is especially vital in commercial buildings, where high traffic and heavy loads are applied to the slab regularly.

To achieve this structural integrity, we must carefully consider the load distribution across the slab. Commercial slabs are often subject to point loads from columns, machinery, or other heavy equipment. These loads can greatly impact the slab's structural integrity if not adequately distributed. This load distribution relies heavily on the slab's thickness, which must be optimized to manage the expected loads efficiently. Additionally, thermal expansion is another critical factor to be addressed. Concrete expands and contracts with temperature changes, and improper consideration of this movement can lead to cracking and weakening of the slab. By considering both load distribution and thermal expansion, we can guarantee the structural integrity of our commercial slab on grade, assuring a safe and functional building space.

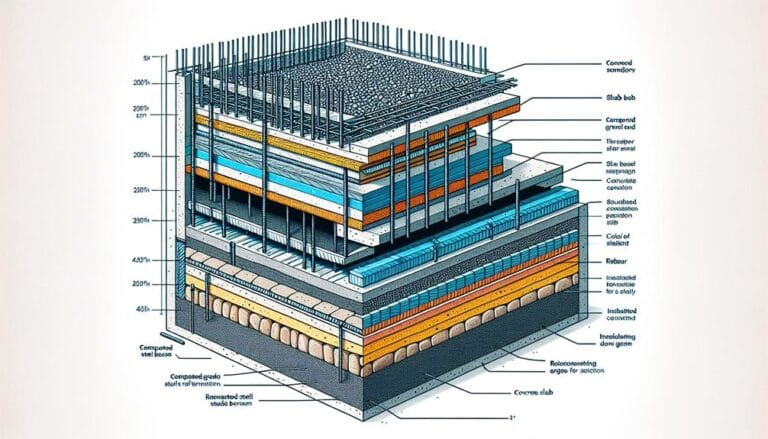

Drainage and Waterproofing

To guarantee the longevity and safety of commercial slab on grade floors, our design must include effective drainage and waterproofing measures to protect the slab and adjacent structures from water-related damage. Water can be very destructive, seeping into foundations and causing structural issues. Therefore, it is crucial to implement systems that prevent water from accumulating around the foundation, beneath the slab, or in the living spaces.

Drainage systems should be well designed. We use a combination of techniques, such as sloping the ground at least 6 inches over 10 feet, to keep rainwater and other surface water from accumulating near the foundation. Additionally, foundation drains can be installed beside the footing to channel water away from the slab, especially on sites with impermeable soils or seasonal pooling issues. These measures guarantee that liquid water and vapor cannot cause damage, cracking, or even mold growth within the structure.

Waterproofing techniques must also be integrated into our design. We use a continuous layer of capillary break/vapor retarder materials between the ground and the slab, including subslab vapor retarders, sill sealers, and waterproofing membranes. This guarantees that water vapor does not migrate upward into the slab and living spaces, preventing issues like dampness and further structural damage. By incorporating these measures, we can create commercially viable and safe slab-on-grade structures.

Site Preparation and Finishing

Evaluating site conditions first guarantees that subslab preparation aligns with the building code and any local regulations specific to water management in our commercial slab on grade construction. This vital step involves understanding the soil type and its properties to ascertain that the subslab will behave as intended. One essential consideration is soil compaction, which must be done to prevent settlement and guarantee even support for the slab.

To achieve proper soil compaction, various excavation techniques can be employed. For instance, we can use site-specific excavation methods to handle different soil types and manage groundwater issues if they arise. Proper compaction assures that the soil will not further settle once the slab is in place, which prevents the development of cracks and other structural issues. By following this systematic approach to site preparation, we can deliver a high-quality, long-lasting slab that meets all project requirements and local building regulations.

Mixing and Placement

The critical process of mixing and placing the concrete is how we bring our slab design to life. Each batch of concrete must be mixed and placed according to specific standards to guarantee that the final product aligns with the design specifications and local building codes. This guarantees we achieve the desired strength and structural integrity.

When it comes to mixing techniques, we need to take into account the right balance of materials, water ratio, and temperature control. Here are a few key factors to keep in mind:

- Mixing Techniques: Proper mixing techniques guarantee uniform distribution of materials and prevent segregation.

- Temperature: Control of temperature is essential as it affects the curing process and final product strength.

- Water Ratio: The right water-to-cement ratio is crucial to achieve the correct consistency and prevent over or under-mixing.

Incorporating these key elements into our mixing and placement process will guarantee our commercial slab on grade meets all requirements and provides the necessary support for our building.

Post-Construction Care

We take immediate action after placing and finishing the slab by applying curing compounds to prevent moisture loss and guarantee ideal strength development. This essential step guarantees that our commercial slab on grade attains its intended durability and withstands the abrasive nature of industrial and commercial use.

In addition to curing compounds, we recognize the significance of thorough joint design and sealing. Proper joint sealing is critical in keeping water and other contaminants out, thereby reducing the risk of erosion and damage. We make certain that our sealants are applied correctly to enable the slab to breathe and, more importantly, to expand and contract freely, reducing the likelihood of cracking.

Following completion, we emphasize the importance of regular surface maintenance in extending the lifespan of the slab. This includes educating facility managers on the correct methods for cleaning and protecting the floor, as well as addressing any crack repair needs promptly to prevent further damage. Overall, our meticulous attention to post-construction care guarantees a durable, low-maintenance commercial slab on grade that meets the demands of industrial and commercial use.

Frequently Asked Questions

How Are Joints in Commercial Slabs Designed for Long-Term Durability?

'To guarantee long-term durability, we strategically design joints in commercial slabs by carefully controlling joint spacing to manage shrinkage and prevent uncontrolled cracking, assuring a stable and reliable foundation.'

What Is the Impact of Climate on Slab Performance?

"We consider how climate factors like temperature variations and moisture control impact slab performance. Ensuring proper joint placement and using effective joint fillers helps mitigate weather-related stress on the slab."

Can Elevated Slab on Grade Be Used in High-Load Applications?

When considering high-load applications, we must carefully evaluate load distribution and select materials accordingly. Elevated slab on grade can be viable if load dispersal is managed effectively, and robust materials are chosen.

How Are Bearing Capacities Determined for Industrial Floor Slabs?

When it comes to heavy-duty industrial floors, we uncover the ground's hidden strength by performing rigorous soil testing methodologies. These exacting methods allow us to accurately determine the bearing capacity calculations, ensuring a solid foundation for our designs.

What Are the Common Regulations for Industrial Slab Design?

When designing industrial floor slabs, we guarantee load distribution is evenly managed. For better structural integrity, we employ reinforcement techniques like rebar or wire mesh to enhance load-carrying capacities and minimize the risk of cracking under heavy loads.