Expert Concrete Slab Design for Commercial Spaces

When designing a concrete slab for commercial spaces, we emphasize foundation stability, especially on clay soils where load distribution and drainage must be carefully managed to prevent settlement and cracking issues. Effective slab design involves selecting the right materials, implementing waterproofing measures, and regular maintenance to guarantee long-term performance. We also focus on durability testing and verification to confirm the slab can withstand constant usage stresses. By considering these essential factors, we create robust, high-quality commercial slabs that meet the unique demands of each project.

Key Takeaways

- Concrete slab design for commercial spaces requires evaluating the soil type, load distribution, and foundation integration for stability.

- Proper soil testing is necessary for optimal design decisions to mitigate structural issues associated with clay soil.

- Reinforcement strategies, including steel rebar, welded wire mesh, fibers, and post-tensioning tendons, enhance structural stability under varying loads.

- Regular seasonal inspections and cleaning debris from slabs prevent wear and tear, ensuring long-term performance and safety.

Design Considerations for Stability

When designing commercial concrete slabs, we must meticulously evaluate several key factors that secure stability and durability, particularly soil type, load capacity, and traffic volume. The type of soil at the site is essential because different soils have varying capacities to bear loads effectively. For instance, clay soils tend to be prone to water retention, which can lead to structural issues if not addressed. Load distribution is also a vital consideration. Making sure that loads are distributed evenly across the slab mitigates the risk of cracking and settlement issues.

Effective foundation integration is critical to guaranteeing the structural integrity of the concrete slab. This involves designing the foundation system to interact seamlessly with the slab, ensuring that both load-bearing elements function as a cohesive whole. Proper soil testing and site evaluation are necessary to determine the best approach for load distribution and foundation integration. By expertly addressing these fundamental design considerations, we can secure that our commercial concrete slabs provide long-term stability and support the needs of the business.

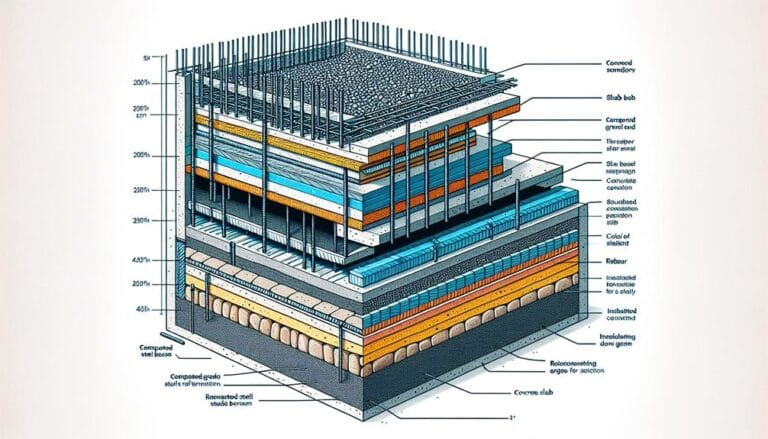

Essential Materials for Commercial Slabs

Selecting appropriate materials is essential in guaranteeing the structural integrity and long-term performance of commercial concrete slabs. When it comes to reinforcement, we have a range of options to choose from, each designed to enhance the slab's strength and durability. We commonly use steel rebar, thanks to its high tensile strength and compatibility with concrete. Other reinforcement materials include welded wire mesh, which offers a more even load distribution, and fibers such as steel, glass, or synthetic varieties that provide additional structural support and resistance to cracking. For larger or more complex projects, post-tensioning tendons are an option, providing robust support for significant loads.

When selecting materials, we also consider the desired finish texture. For instance, a smooth, high-gloss finish might be ideal for warehouses with heavy equipment traffic, while a textured finish can improve traction in high-traffic areas. The choice of materials ultimately depends on the project's specific demands, user requirements, and environmental conditions. By carefully balancing these factors, we can guarantee our commercial slabs perform at their best and withstand the rigors of daily use.

Steps for Efficient Waterproofing

To guarantee the long-term performance of our commercial concrete slabs, we prioritize efficient waterproofing measures at every stage of the construction process. Protecting our slabs from water penetration and damage is vital to prevent structural issues, safeguarding the integrity of the building and guaranteeing a safer, healthier environment. We begin by installing high-quality moisture barriers, carefully selecting materials tailored to each project's specific needs. These barriers shield the slab from moisture rising from the sub-grade, thereby reducing the likelihood of issues such as mold growth and structural weakening.

Next, we implement drainage solutions to facilitate water runoff and minimize the accumulation of water around the slab. This includes strategically placed drainage channels and sloping the slab to direct water away from the structure. Additionally, we verify that all joints and connections are properly sealed to prevent water ingression. By adopting these measures, we can confirm that our commercial concrete slabs remain watertight and function effectively throughout their service life, providing long-term reliability and benefiting both the building occupants and the environment.

Effective Maintenance Techniques

Effective Maintenance Techniques

We thoroughly guarantee our waterproofing measures are sustained by putting in place proactive maintenance routines, regularly inspecting and addressing potential vulnerabilities in our slabs to maintain their integrity and performance. At the heart of a well-functioning slab lies the ability to stay ahead of problems, and preventive maintenance is essential in preventing damage. By regularly monitoring our slabs, we can catch potential issues before they escalate, thereby saving costs and minimizing downtime.

To ascertain the effectiveness of our slabs, we adhere to the following practices:

- Seasonal Inspections: Regular seasonal inspections help us identify any seasonal wear and tear, allowing us to take prompt action to rectify any issues.

- Cleaning Debris: We maintain our slabs by making sure they are free of debris, which helps prevent cracks and other structural issues.

- Water Drainage Management: Effective water drainage management is vital to preventing moisture accumulation and potential damage.

Cost Analysis and Budgeting

We meticulously assess the financial implications of maintaining and repairing commercial slabs to guarantee we allocate resources efficiently, avoiding costly surprises down the line. As part of our cost analysis, we create a detailed budget breakdown that accounts for every aspect of the project, from initial design and materials to ongoing maintenance and potential repairs.

To ascertain an accurate budget forecast, we evaluate each component of the project, including labor costs, materials, and any required permits or licenses. By doing so, we can pinpoint areas where we can optimize our resources and reduce costs without compromising the structural integrity or aesthetic appeal of the slab. This approach allows us to provide our clients with a clear and thorough financial plan, helping them make informed decisions about their investment. By prioritizing cost analysis and budgeting, we are able to deliver high-quality commercial slabs that meet both our clients' budget and their functional requirements.

Safety Features for Heavy Traffic

To guarantee a safe and durable concrete slab for commercial spaces, it is vital to incorporate safety features tailored to handle heavy traffic loadings.

Standardizing safety protocols for heavy traffic loadings is essential to confirm that our commercial slabs withstand any worst-case scenarios. Heavy equipment and repeated traffic can lead to excessive wear and tear, potentially causing accidents and damage to the infrastructure. Consequently, we must prioritize safety features that address the specific demands of high-traffic commercial areas.

Here are three important safety features to take into account:

- Thicker Slabs: A minimum thickness of six inches for areas with heavy machinery is essential to maintain stability and prevent excessive deflection.

- Slip Resistance: Confirm the slab surface has sufficient slip resistance, both initially and over time, by using textured finishes or applying treatments that maintain traction.

- Maintenance Access: Facilitate regular inspections and maintenance by including accessible inspection points and confirming that the slab design allows for easy equipment maneuverability.

Durability Testing and Verification

By conducting rigorous durability testing and verification, we guarantee that our concrete slabs can stand the test of time in high-traffic commercial spaces. Durability is vital because it directly impacts the safety, functionality, and longevity of a facility. Our extensive testing includes evaluations of load-bearing capacity, which is essential for commercial spaces dealing with heavy equipment and dynamic loads. We make certain that the concrete slab can withstand the stresses of constant usage, taking into account factors like deflection, shear strength, and compressive strength.

To achieve exceptional durability, we employ structural reinforcement methods such as rebar or fiber-reinforced polymers. These reinforcements greatly enhance the slab's ability to resist cracking and make sure that the structure remains stable under various loads and environmental conditions. In addition, regular maintenance plays an important role. We develop thorough maintenance plans that include regular inspections, repairs, and updates to guarantee that the slab continues to perform at its best. Our commitment to robust durability testing and verification guarantees that our concrete slabs provide a solid foundation for commercial spaces, allowing them to operate efficiently and safely over the long term.

Frequently Asked Questions

Is It Necessary to Add a Vapor Barrier Beneath a Commercial Slab?

We believe it's essential to install a vapor barrier beneath a commercial slab to effectively control moisture and prevent issues like sweating slabs, efflorescence, and long-term curling, ensuring structural integrity and a durable finish.

Can a Monolithic Slab Be Poured in Sections Over Multiple Days?

We can pour a monolithic slab in sections over multiple days by controlling the joint placement and using specialized pouring techniques to guarantee even slab curing and prevent curling issues.

Should a Concrete Sump Be Integral to the Slab or Separate?

Like Atlas holding up the heavens, our concrete masterpiece can include a sump. We prefer a separate sump pump installation for efficient drainage considerations and easier maintenance.

How Can Joints in the Slab Be Designed to Minimize Cracking?

To minimize cracking, we guarantee crack control by spacing joints appropriately. We place control joints at least 1/4 of the slab's thickness deep and 8-12 feet apart for 4' thick pours.

Can a Slab Be Designed for Both Heavy Vehicle and Foot Traffic?

Imagine a checkerboard of steel and concrete working together seamlessly. We can indeed design a slab for both heavy vehicle and foot traffic by focusing on the slab's load capacity and ensuring a durable surface finish.