The 7 Essential Commercial Slab Construction Secrets

It is understood that building commercial slabs can be a complex and expensive endeavor but what if we told you there are ways to keep costs in check and efficiency high? Tilt-up construction is one of these methods, offering lowered labor costs and material expenses with precast panels, streamlined materials handling and optimized building processes. It's a sustainable and profitable option, but there's more to it. Effective project scheduling can prevent delays and regular inspections guarantee proper curing. Understanding load distribution and site conditions are also essential. And that's just the beginning – we've uncovered the secrets to help you build better, smarter and more efficiently.

Key Takeaways

- Detailed site preparation: Ensure thorough soil testing, compaction, and drainage to prevent settling and cracking issues.

- Structural integrity: Reinforcement materials, such as rebar, must be strategically placed to distribute loads evenly.

- Design considerations: Effective load distribution and post-tensioning techniques enhance strength and prevent cracking susceptibility.

- Material selection: Use high-quality concrete mixes and additive materials to ensure durability, strength, and workability.

Disputing the Cost

The 7 Essential Commercial Slab Construction Secrets

As construction teams calculate their costs for commercial slabs, several questions arise regarding the expense of traditional concrete slab construction methods. Understanding that cost estimation plays a significant role in determining profitability, it is vital to look beyond the conventional approach. The industry's persistence with cement-based solutions contributes to higher material and labor costs. This calls for a rethink of our pricing strategies to account for the evolving landscape of commercial builds.

One approach is the adoption of innovative materials and methods, such as the tilt-up construction technique, which leverages the efficiency of reinforced concrete to streamline the process and reduce labor costs. Utilizing prefabricated building components also simplifies the construction process, curbing costs associated with manual labor and project timelines. Evaluating these alternatives will allow us to challenge traditional cost structures and create a new wave in commercial slab construction pricing.

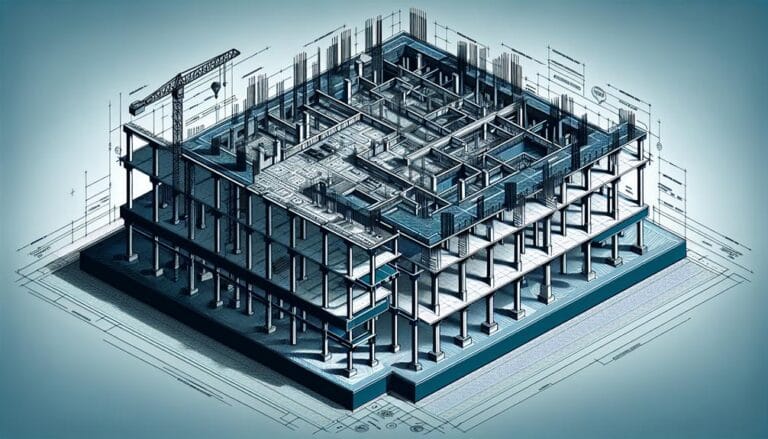

Structural Integrity

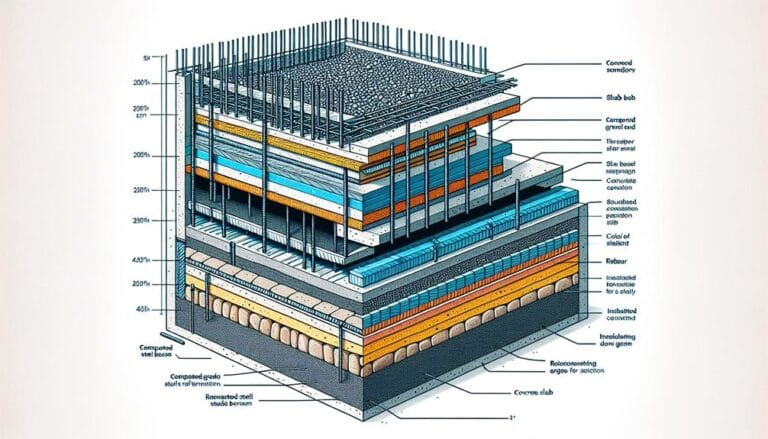

Knowing that structural integrity is vital in guaranteeing the stability and lifespan of commercial slabs, we must move beyond just estimating material costs and labor hours. The primary focus should be on load distribution and how it affects the entire structure. Effective load distribution is essential to preventing cracks and making certain the slab can handle the intended load capacity. This can be achieved through carefully designing and specifying the subgrade, subbase, and slab thickness. Additionally, the design should address alignment with the building's layout and any specific local conditions.

Reinforcement techniques such as post-tensioning are critical for commercial slabs. Post-tensioned slabs contain steel cables that run throughout the slab, providing additional strength and reducing susceptibility to cracking and structural instability. These systems help builders achieve greater load-bearing strength and are particularly helpful in areas where soil conditions are poor. Effective use of vapor retarders and careful selection of subbase materials, such as crusher run over #57 stone, also contribute to a more stable commercial slab. By focusing on load distribution and reinforcement techniques, we can guarantee the long-term durability and safety of our commercial slab construction projects.

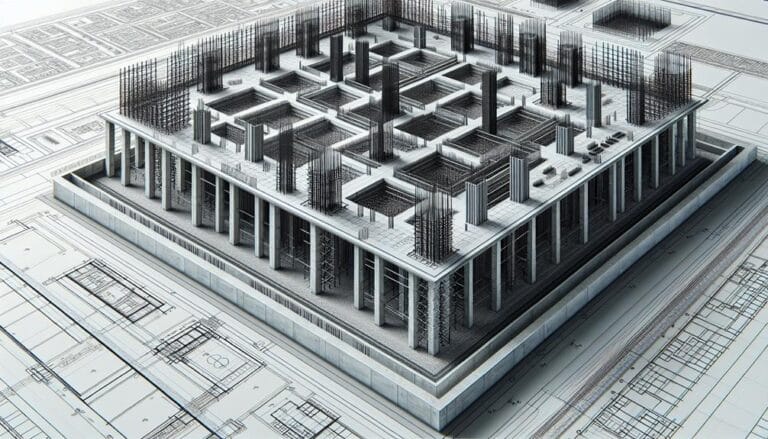

Site Preparation

As commercial slab construction experts, we carefully assess site conditions by performing detailed visual inspections and geotechnical evaluations to confirm the ground can support the commercial slab's intended load capacity. This includes screening for any hidden underground obstacles that may compromise the structural integrity of the slab. By conducting thorough site surveys and soil testing, we can pinpoint potential issues such as unstable soil, inadequate drainage, or inadequate ground bearing capacity. These assessments guide our site grading strategies, confirming that the ground is leveled and even, thereby preventing uneven settlement and structural stress.

Additionally, these evaluations help us determine the suitable subgrade material and confirm it is correctly compacted. For example, we use materials like crushed stone for the subbase, and compact it to the required density. This attention to detail at the site preparation stage enables us to build a solid foundation for our commercial slabs, which, in turn, enhances the overall durability and stability of the structure.

Building Regulations

We adhere to local zoning codes and building regulations to confirm that our commercial slabs meet all necessary structural and safety standards. This means meticulously following the requirements set by local authorities to ascertain our slabs meet the demanded specifications.

In this process, we carefully examine and verify all necessary permit requirements. This further certifies complete compliance with regional zoning laws and building codes. By doing so, we avoid any potential issues during and after construction, confirming that our commercial slabs stand the test of time without compromising on structural integrity and functionality.

Our rigorous compliance with building regulations also translates to enhanced safety for the structures we build. This scrutiny extends to every detail, affirming that even the smallest aspects meet the high standards demanded by local authorities. This commitment to compliance sets us apart and underscores our dedication to delivering premium commercial slabs that last and perform as intended.

Water Resistance

To guarantee our commercial slabs maintain their structural integrity and functionality, we focus on water resistance by implementing advanced drainage systems and water-resistant materials. This involves carefully selecting and applying effective moisture barriers to prevent water infiltration and guarantee a long-lasting structure. For instance, incorporating a durable waterproof membrane around the footing and foundation walls considerably reduces the risk of water penetration and subsequent damage.

Our thorough drainage systems guarantee any water that may gather around the slab is quickly and efficiently redirected away from the foundation. This includes using a dimpled mat under the plywood subflooring, which prevents water from accumulating. Additionally, we apply a water-resistant barrier around the foundation, guaranteeing that any groundwater or surface water that might infiltrate is quickly drained off. By diligently implementing these measures, we guarantee that our commercial slabs effectively repel moisture, safeguarding the structural integrity and extending the life of the facility.

Construction Timeline

Implementing advanced drainage systems and water-resistant materials on schedule guarantees our commercial slabs meet construction deadlines. Effective project scheduling is critical to avoid costly construction delays. When it comes to commercial slab construction, Timing is everything. Delayed installations of drainage systems, vapor barriers, or other components can lead to significant setbacks and compromise the structural integrity of the slab.

To make certain our projects stay on track, we create detailed timelines for each stage of construction. By doing so, we can identify potential issues before they arise and swiftly address them. Our thorough planning includes coordination with suppliers and contractors to make certain all necessary materials and labor are available when needed.

Additionally, we emphasize the importance of regular inspections to catch any potential problems early on. This proactive approach allows us to address any concerns promptly, preventing them from escalating into major issues that could jeopardize the project's progress.

Post-Construction Care

Once the slab is built, our focus shifts to ensuring it remains durable and leak-free. This begins with proper post-installation maintenance. It's essential to regularly inspect the slab for any signs of cracks, eroding, or shifting. We check for exterior and interior water exposure, paying close attention to areas around pipes, joints, and edges. Our teams inspect for signs of wear and tear, addressing any issues promptly to prevent more significant problems from arising.

To extend the lifespan of our commercial slabs, we explore various surface treatment options. This might include applying sealants, epoxy coatings, or acrylic finishes. These treatments protect the slab from environmental factors and enhance its overall integrity. They also improve aesthetics, ensuring the slab remains visually appealing while maintaining its structural health.

Frequently Asked Questions

What Type of Reinforcement Is Used for Temperature Change Resistance?

On projects requiring temperature change resistance, we use macro-synthetic fibers for reinforcement as they effectively reduce cracks caused by thermal expansion, offering improved durability and structural support while minimizing shrinkage.

Are All Slabs on Ground Designed for Structural Loads?

No, not all slabs on ground are designed for structural loads. Slab design considerations include whether they're for vertical supports, lateral ties, lateral-load transfer, or lateral bracing, impacting load handling capabilities.

Can Concrete Slabs Be Used for Both Tension and Compression?

To clarify, we need to understand that slabs can indeed handle both tension and compression. Specifically, they must meet specific tension requirements and compression strength standards, ensuring structural integrity and load-bearing capacities to prevent common issues like cracking and collapse.

Are SOG Always Designed to Resist Horizontal and Vertical Loads?

"For us, the answer is no – not all concrete Slabs-on-Ground (SOG) are designed to resist both horizontal and vertical loads; proper load distribution and thorough soil preparation are critical in SOG design."

How Does ACI 360R Guide Slab-On-Ground Design?

"We use ACI 360R to guide slab-on-ground design by considering the interaction between the slab and supporting materials, ensuring proper soil preparation and considering design load magnitudes and responses, as well as necessary reinforcement for structural resistance."