What to Consider in Commercial Concrete Slab Design?

When designing a commercial concrete slab, it is understood that incorporating appropriate foundation types, robust load calculations, and thermal considerations are essential for structural durability. We also consider reinforcement strategies, effective drainage systems, and surface finishes to guarantee long-term stability. By integrating these factors, we can assure a robust and effective commercial slab. To maximize this, understanding terms like T-shaped foundations for cold climates, thermal mass benefits, and specific finish selections for various settings are vital.

Key Takeaways

- Structural Requirements: Ensure slab design meets intended load and site characteristics to prevent cracking and settlement.

- Foundation Depth: Adequate depth is crucial to address frost heaving and ensure exterior wall support.

- Drainage Facilitation: Add a layer of sand or gravel under the slab to enhance drainage and prevent movement.

- Load Calculation and Analysis: Evaluate load distribution across the slab and assess slab capacity to ensure structural integrity.

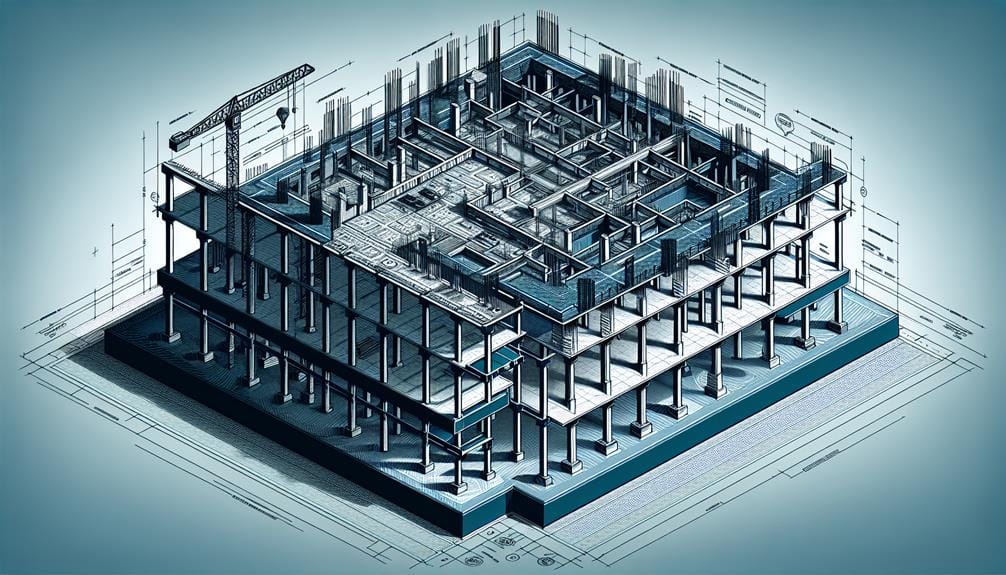

Types of Commercial Slabs

As we explore the world of commercial concrete slabs, we're faced with a variety of options to evaluate, each designed to handle unique load requirements and aesthetics. Among the main types, we have T-shaped concrete foundations, ideal for taller structures and colder climates where ground freezing occurs. These foundations require a strong anchor system and pinpoint inspectors to verify the slab strength through break tests.

Another option is the slab-on-grade foundation, which is one solid slab with reinforced rods, typically used in regions without ground freezing risks. To prevent cracking, wire mesh is often added. Finally, the frost-protected foundation utilizes insulation sheets to maintain heat, allowing for single pouring.

Here, precision in design is vital. For instance, precast slabs can be used for specific architectural features, whereas standard slabs must meet specific slab thickness requirements. Proper design guarantees a strong foundation and lasting structure.

Integration of these options involves examples, calculations, and technical specifications to confirm the right choice for each commercial project.

Foundation Design Considerations

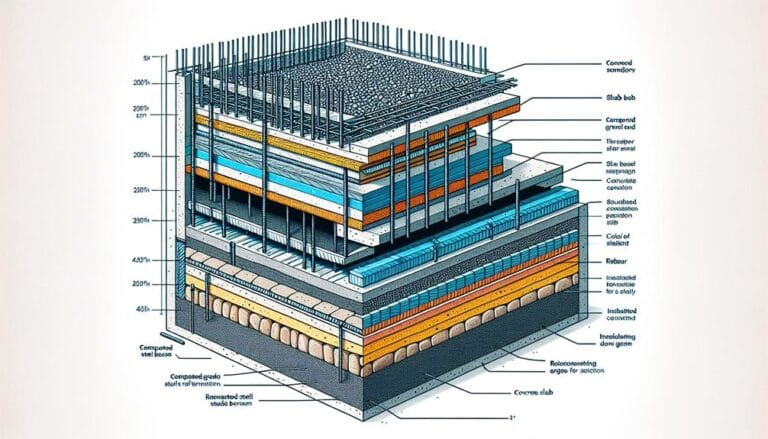

When designing a commercial concrete slab's foundation, the first step is to identify the fundamental structural requirements and site-specific characteristics that need to be accounted for in the overall design. This includes understanding the soil composition, which plays an essential role in guaranteeing the slab can support the intended loads without significant settlement or cracking.

Foundation depth is another significant consideration. Regardless of the slab type, whether it's a monolithic or stem wall foundation, the depth must be adequate to address frost heaving and provide sufficient support for the exterior walls. Confirming the foundation is placed on undisturbed soil or a compacted base is also critical. Additionally, a layer of sand or gravel is usually added to facilitate drainage and prevent future movement. Geotechnical soil tests help determine the precise thickness and composition required for a stable foundation, which is particularly important for high-traffic or heavy-load environments. By carefully addressing these factors, we can guarantee the foundation effectively supports the building, maintaining its structural integrity while minimizing potential maintenance and replacement costs.

Load Calculations and Analysis

In the design of a commercial concrete slab, load calculations and analysis play a critical role in guaranteeing the slab can support the intended loads and stresses effectively. We then conduct load calculations and analysis to determine the slab's necessary reinforcement, guaranteeing ideal distribution of loads and stresses. Here are the key elements we focus on during this process:

- Load Distribution: Carefully evaluating how the loads will be distributed across the slab, considering factors such as the type of building, occupancy, and equipment to be installed.

- Weight Capacity: Determining the weight capacity of the slab, taking into account the thickness of the slab, the strength of the concrete, and the support from the subgrade.

- Reinforcement Design: Calculating the required reinforcement to guarantee the slab can handle the anticipated loads, including both static and dynamic forces.

Thermal Mass and Insulation

We optimize the thermal mass and insulation of our commercial concrete slabs to minimize the impact of temperature fluctuations on the structure, ensuring enhanced energy efficiency and a longer lifespan. This thoughtful approach not only saves energy and reduces emissions but also contributes to a more comfortable working environment for building occupants.

| Structural Component | Thermal Performance | Energy Efficiency |

|---|---|---|

| Concrete Slab | Beneficial thermal mass | Moderately impacts energy efficiency |

| Insulation | Reduces heat transfer | Highly impacts energy efficiency |

| Vapor Barrier | Prevents moisture penetration | Low impact on energy efficiency |

Effective use of thermal mass and insulation in commercial concrete slabs is essential for maintaining a consistent indoor climate and reducing the load on heating and cooling systems. By strategically locating insulation, vapor barriers, and structural elements, we can maximize the thermal performance of our slabs, leading to cost savings and a more environmentally friendly structure.

Reinforcement and Structural Integrity

Ensuring structural integrity, we employ strategically arranged reinforcement within our commercial concrete slabs to withstand heavy loads and environmental stresses, ensuring the safety and durability of the structure. This is a vital aspect of slab design, as the reliability of the slab directly affects the comfort and safety of users. Here are some key points to evaluate:

- Effective Rebar Placement: The arrangement of reinforcement (rebar) plays a significant role in maintaining structural integrity. Proper placement of rebar helps to evenly distribute loads, mitigating the risk of cracking and improving overall durability.

- Crack Control Measures: To minimize the adverse effects of cracking, we use techniques such as ensuring correct concrete mix proportions, optimizing rebar spacing, and employing anti-shrinkage additives. These measures help to reduce the likelihood of cracks forming and mitigate the damage if they do.

- On-Site Testing: Through methods like Schmidt rebound hammer tests and ultrasonic pulse velocity testing, we can measure the strength and reliability of our slabs. Such analysis assists in evaluating the slab's ability to handle loads and predict potential issues.

Drains and Waterproofing Systems

Implementing effective drains and waterproofing systems is vital in commercial concrete slab design to prevent water ingress and minimize the risk of damage from moisture and corrosive substances. As we consider the design of commercial concrete slabs, we must not overlook the significant role that drains and waterproofing systems play in maintaining the integrity and functionality of the structure. Drainage systems are essential in directing water away from the slab and guaranteeing that the underlying sub-grade and sub-base remain stable and dry. This is particularly important for slabs that support significant loads, such as in industrial settings.

To guarantee complete protection, we incorporate advanced waterproofing techniques into our design. These techniques include the use of waterproofing membranes, drainage boards, and insulation, which work together to prevent water penetration and damage. By combining these elements, we can create a highly effective and reliable waterproofing system that safeguards the slab from water-related issues. Effective drainage and waterproofing are key components of a successful commercial concrete slab design, guaranteeing a long-lasting and functional structure.

Surface Finishes and Durability

With waterproofing in place to prevent moisture damage, our goal now shifts to selecting surface finishes that enhance durability while meeting aesthetic and functional requirements. The correct choice of finish is essential to guarantee the long life and performance of the slab. For commercial spaces, this decision becomes even more vital, as the slab will be subjected to heavy foot traffic or machinery.

- Aesthetic Options: A variety of finishes are available, each with its own surface aesthetics. From simple, compacted concrete to advanced epoxy or polyurethane coatings, the options cater to diverse design demands.

- Durability Factors: The maintenance requirements of the chosen finish must be considered. For instance, some coatings require periodic reapplication, while others need regular cleaning to prevent damage.

- Functionality Considerations: Functionality also plays a significant role in the selection of a finish. For example, epoxy coatings provide high chemical resistance, making them ideal for industrial settings.

Frequently Asked Questions

What Are Common Signs of Slab Damage or Structural Issues?

"We must keep a weather eye open for common signs of slab damage or structural issues, such as unusual cracking patterns, moisture intrusion, and sudden structural shifts, which can lead to significant foundation repair costs."

How Often Should Commercial Slabs Be Inspected for Maintenance?

To guarantee the longevity of our concrete slabs, we should implement a regular inspection frequency, scheduling routine check-ups every six to twelve months to catch any potential issues and maintain our buildings effectively.

Can Slab Design Be Adapted for Extreme Weather Conditions?

Here is a 35-word answer to the current question:

"We often wonder if slabs can defy the fury of Mother Nature. But, thankfully, designers can adapt slab design for extreme weather conditions by incorporating thermal insulation and robust moisture control for a resilient and long-lasting foundation."

Are There Any Environmental Impacts of Using Certain Slab Materials?

'As designers, we must admit that certain slab materials pose significant environmental impacts. For better sustainability, we opt for recycled aggregates and eco-friendly materials to lower our carbon footprint and guarantee environmentally sensitive projects.'

How Does the Subgrade Affect the Lifespan of the Slab?

When preparing a subgrade, we recognize that proper load distribution is essential for extending the lifespan of the slab. Neglecting subgrade preparation can lead to structural issues, settlement, and heaving, greatly shortening the slab's lifespan.