Commercial Concrete Slab Installation Steps

As we prepare to install a commercial concrete slab, we start by ensuring the site is clear of debris and organic materials for a stable base. We then assess drainage considerations, including slope and gradient to prevent water accumulation. Importantly, we verify soil compaction to avoid cracking or shifting of the slab. Next, we conduct soil testing for bearing capacity and density to identify stabilization needs. With meticulous site preparation, we can maximize the lifespan and structural integrity of the slab. If you're looking to learn more about the steps involved in commercial concrete slab installation, keep going to explore the details of formwork installation, subbase preparation, concrete pouring and finishing, and curing and quality control.

Key Takeaways

- Clear the site of debris and organic materials to ensure a stable base for the slab.

- Conduct soil testing and compaction to prevent issues like settlement and cracking.

- Build level, square, and secure formwork for accurate and stable concrete pouring.

- Pour concrete mixture carefully to avoid air pockets and trapped water and ensure a smooth finish.

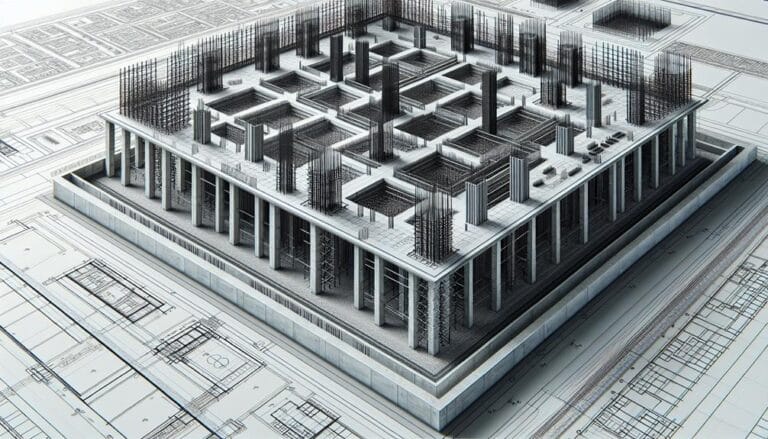

Site Preparation and Grading

Our first task is to clear the area of any debris and organic materials to assure a well-prepared base for the slab. This vital step lays the groundwork for a successful commercial concrete slab installation. We systematically remove trees, rocks, and other obstacles to guarantee a level and stable foundation.

Simultaneously, we assess the drainage considerations for the site. This includes evaluating the slope and gradient of the land to assure that no water accumulation occurs. We also verify that the soil is adequately compacted. This step is essential in preventing any cracking or shifting of the slab due to uneven settlement.

We conduct thorough soil testing to determine the soil's bearing capacity and density. This information helps us to identify areas where additional compaction or stabilization may be needed. By meticulously preparing the site, we create an ideal environment for the concrete slab to be installed, thereby maximizing its lifespan and structural integrity. Our team's meticulous attention to detail during site preparation guarantees a robust and long-lasting commercial concrete slab installation.

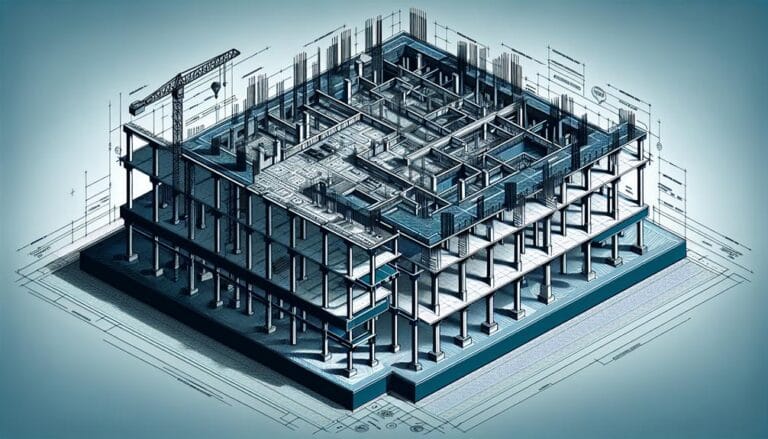

Formwork Installation

Now that the site has been thoroughly prepared, we focus on installing formwork that will define the shape and grade of the slab. The process begins with selecting the right formwork materials, which can include conventional lumber, durable steel, or high-quality aluminum. We consider the specific needs of our project, such as the dimensions and complexity of the slab, when choosing the appropriate materials.

There are various types of formwork to employ, ranging from traditional wood forms to advanced modular systems. The specific type is determined by the project's requirements, guaranteeing the slab is constructed with precision and stability. For instance, if we need to create intricate shapes or curves, we might opt for modular formwork that provides greater flexibility.

Once we have the necessary formwork materials and type, we carefully construct the forms to make certain they are level, square, and secure. This involves hammering stakes at regular intervals to maintain the frame's position and employing a consistent bracing system to prevent any movement during the concrete pouring process. With our formwork in place, we are ready to move on to the next critical phase of commercial concrete slab installation.

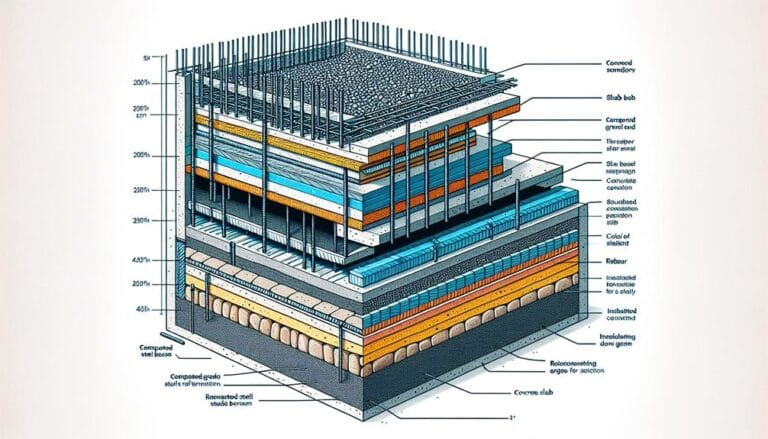

Subbase Preparation

We meticulously prepare the subbase by guaranteeing a smooth and uniform surface to support the concrete slab. This critical step is essential for a stable and even base that prevents potential issues like scaling and spalling. We carefully evaluate the site's soil conditions and adjust our methods accordingly. For instance, in areas with expansive soils or high water tables, we employ specialized drainage solutions to mitigate the risks of heaving and settlement.

Soil compaction is another key element in subbase preparation. We compact the soil in layers, carefully monitoring the density to guarantee uniform support for the slab. This prevents any voids or weak spots that might lead to structural issues later on. By taking the time to expertly prepare the subbase, we lay the foundation for a durable and long-lasting concrete slab that meets the highest construction standards.

Next, we'll move on to the installation of formwork, which marks a significant milestone in the concrete slab installation process.

Concrete Pouring and Finishing

Upon establishing a properly prepared subbase, we move on to pouring and finishing the concrete, where meticulous timing and technique serve as the cornerstones for a durable and high-quality slab. First, we verify our concrete mix design is tailored to meet the site's conditions and requirements. This includes selecting the right type and proportion of cement, water, and aggregates to guarantee the ideal concrete strength.

Next, we carefully pour the concrete mixture onto the subbase, taking care to avoid any air pockets or trapped water. We use leveling tools and finishing techniques such as tamping and screeding to achieve a smooth and level surface. Attention to detail is vital here, as an improper pour can lead to cracks and other structural issues.

Once the concrete is poured and leveled, we allow it to cure, applying the necessary finishing touches once it has reached the desired strength. This may include applying a sealant to protect the slab from wear and tear or enhancing its aesthetic appeal with various finishing techniques. Our thorough procedure guarantees that the final product is sturdy, functional, and visually appealing, meeting the demands of commercial spaces while minimizing future maintenance needs.

Curing and Quality Control

For ideal strength and durability, we guarantee the curing process is meticulously controlled, as the first 48 hours are critical to the concrete's final integrity. During this period, we employ expert curing techniques to guarantee a homogenous and stable concrete slab.

We use liquid chemical curing compounds to slow down the hydration process, mitigating the risk of cracking and curling. These compounds enhance the concrete's ability to cure slowly and evenly, minimizing surface discoloration and strengthening the slab's core.

Our quality assurance protocols include regular site visits to inspect the curing process. We verify that the curing compound is consistently applied, and the slab is protected from extreme temperatures and weather conditions. Additionally, we perform rigorous strength tests to confirm that the slab meets the specified strength and quality requirements.

We understand the importance of proper curing and quality control in delivering a long-lasting and high-performance concrete slab that meets the highest industry standards. Our meticulous attention to detail guarantees that every aspect of the curing process is precision-controlled, assuring the final product is a reflection of our expertise and dedication to quality.

Frequently Asked Questions

Can I Pour Concrete on My Own, or Do I Need a Professional?

"Pouring concrete is like cooking a recipe – if done right, it's a masterpiece, but one wrong step can lead to a messy fail. For small projects, DIY saves money, but for larger ones, professional help might be worth the investment."

How Do I Ensure the Slab Remains Durable and Crack-Free Over Time?

To guarantee our slab remains durable and crack-free, we focus on proper thickness and robust reinforcement techniques, including mesh and rebar placement, thorough preparation, and adequate curing to minimize shrinkage and maximize structural integrity.

What Safety Measures Are Crucial During the Concrete Pouring Process?

As we commence on the concrete pouring journey, we safeguard against potential perils with due diligence by donning safety gear and meticulously preparing the site, ensuring every step towards a crack-free slab is paved with prudence.

How Do I Protect the Slab From Water Damage and Erosion?

To protect our slab from water damage and erosion, we must guarantee effective waterproofing techniques and adequate drainage solutions. This includes using hessian, plastic sheeting, and surface densifiers to maintain a solid, water-resistant surface.

What Maintenance Is Required for the Slab After Completion?

As part of our standard maintenance, we guarantee the slab is properly sealed and regularly clean the surface to prevent water damage and erosion, guaranteeing the foundation's longevity and structural integrity.