Top 10 Tips for Concrete Driveway Resurfacing Contractors

When it comes to concrete driveway resurfacing, we understand that several factors are essential for a successful project. We need to choose experienced contractors with a track record of successful projects. A thorough inspection of the existing concrete conditions is critical to identify necessary repairs and enhance durability. Then, we need to plan the base material and preparation to guarantee a strong bond with the resurfacing material. We should also take into account durable finishes, budget options, and environmental impact. Additionally, we need to evaluate maintenance efforts, stamped and stained options, permits, and warranties. From materials to regulations, we need to take into account every detail to achieve a long-lasting, high-quality driveway resurfacing.

Key Takeaways

- Ensure the contractor has extensive experience in concrete resurfacing and a proven track record of successful projects.

- Conduct thorough inspections of existing concrete to identify necessary repairs and enhance durability.

- Plan base material preparation by assessing conditions, filling cracks, and enhancing adhesion for optimal results.

- Select durable finishes that withstand harsh conditions, considering factors like traffic exposure and local climate.

Choose Experienced Concrete Contractors

When choosing a contractor for your concrete driveway resurfacing project, make certain to look for a professional who has extensive experience and a proven track record of success in the field. There is no substitute for a well-seasoned expert. Experts in concrete resurfacing will have refined their skills over time, guaranteeing they possess the necessary know-how to handle any potential issues that may arise during the project. Here, we dig into the importance of hiring a knowledgeable contractor.

Experienced contractors need to adhere to a set of strict guidelines. Their qualifications must align with the specific requirements of your project. For instance, if you want to apply an epoxy coating, make certain your contractor has experience with epoxy applications. Industry experience counts heavily, and a contractor with extensive knowledge guarantees high-quality work that meets your expectations.

Inspect Existing Concrete Conditions

Before we begin resurfacing our concrete driveway, we need to scrutinize the existing conditions to confirm any necessary repairs are made to avoid future problems. Inspecting the current state includes a thorough crack assessment and surface evaluation. This initial assessment is essential as it helps identify cracks, uneven areas, stains, and any other damage that needs repair. We must also verify the driveway does not require more extensive work than a simple resurfacing. This detailed examination prevents potential issues from resurfacing and guarantees the new coating adheres properly, leading to a more durable and longer-lasting result.

During the inspection, we look for any signs of structural damage or water seepage that could impact the success of our resurfacing project. If we find any significant cracks, we make certain to mark them for filling and cleaning to ensure a strong bond between the old concrete and the repair material. This initial step is vital to achieving a professional-looking finish and preventing further damage to the driveway. By meticulously evaluating the existing conditions, we can confidently move forward with the resurfacing process.

Select Durable Concrete Finishes

To confirm the resurfacing project yields a durable and visually appealing finish, we carefully select the right concrete finishes that can withstand harsh environmental conditions and maintain a pristine appearance over time, choosing from options like sealers, coatings, and decorative finishes that fit our driveway's design and functionality.

When it comes to finish durability, several factors come into play. We consider the driveway's exposure to foot and vehicle traffic, the local climate, and the drainage system in place. For instance, high-pressure washes can help guarantee a strong bond between the old concrete and the new material, while a non-slip finish can prevent accidents during rainy days. We also explore concrete texture options to enhance both the aesthetic and functional aspects of the driveway.

For a decorative finish, we might use stamping tools or textured rollers to create patterns and textures. Acid washing and high-pressure water blasting can also be effective means to extensively clean the surface, which is vital for effective bonding. Finally, we weigh the benefits of applying epoxy coatings or sealers to protect against stains, fading, and freeze-thaw cycles. By carefully balancing these factors, we achieve a finish that not only looks great but also stands up to the demands of daily use.

Plan Base Material and Prep

As concrete driveway resurfacing contractors, we prioritize thorough preparation of the base material by meticulously evaluating its condition and applying the necessary treatments to assure a strong bond between the old concrete and the new resurfacing material. To do this, we assess the driveway to pinpoint cracks, uneven areas, stains, and any other damage that needs repair. This helps to determine which base material is suitable for the specific project.

During surface preparation, we guarantee that any cracks or holes are filled using a concrete patching compound and that all loose debris is removed. For more thorough cleaning, we use pressure washers to remove dirt and contaminants. Additionally, we etch the surface mechanically or chemically to enhance the adherence of the resurfacing material.

| Step | Description

| — | —

| 2 | Surface Cleaning

| — | —

| | Clean the driveway to remove debris and dirt.

| 3 | Repair Cracks

| — | —

| | Fill any cracks or holes using a concrete patching compound.

| 4 | Etching or Grinding

| — | —

| | Use etching or grinding to enhance adhesion.

Budget for Resurfacing Options

Budget for Resurfacing Options

We start budgeting for the resurfacing options while considering the range of choices that best suit the driveway's specific needs. Whether the aim is to revamp the driveway aesthetically or simply guarantee its functionality, a budget that aligns with these goals is essential. Here are the key budget considerations:

- Cost Effective Materials: Our primary focus is on choosing materials that are budget-friendly without compromising on durability and appearance. This includes using cement-based resurfacers, which are often a more cost-effective option compared to polymers or other advanced materials.

- Resurfacing Techniques: The choice of technique can have a significant impact on the budget. For instance, grinding and etching might be more expensive than applying a bonding agent. By selecting the appropriate method for the specific driveway conditions, we can keep costs in check.

Evaluate Environmental Impact

While we weigh the financial implications of resurfacing, we must simultaneously consider the ecological impact of the materials and methods we choose. This is essential as contractors responsible for resurfacing concrete driveways. It's imperative that we adopt sustainable materials and eco-friendly practices to minimize the environmental burden of our work.

Communities and the Environment

Understanding the eco-footprint of our projects is significant. Eco-friendly resurfacing involves using materials with lower carbon emissions during production. Incorporating such sustainable materials into our methods helps to reduce both immediate and long-term damage to the environment. This includes evaluating the water usage, energy consumption, and waste management associated with each material we use. We endeavor to minimize waste and optimize the lifespan of our resurfacing projects to reduce the need for future tear-outs and replacements. By embracing environmentally conscious practices, we create a healthier living space for our communities.

Consider Maintenance Efforts

We must meticulously develop and implement maintenance routines to assure the durability and sustainability of our resurfaced concrete driveways. A properly designed maintenance plan guarantees that our hard work lasts for years to come, which is essential for long-term durability and overall customer satisfaction.

Here are some key aspects of our maintenance routine:

- Regular Cleaning: Regular cleaning is essential to remove dirt and debris that can cause damage. This can be achieved through routine pressure washing using mild detergents.

- Sealing and Coatings: Periodically applying sealants or specialty coatings helps protect the driveway from environmental factors like UV rays, water, and chemicals. This proactive approach prevents damage and maintains that fresh new look.

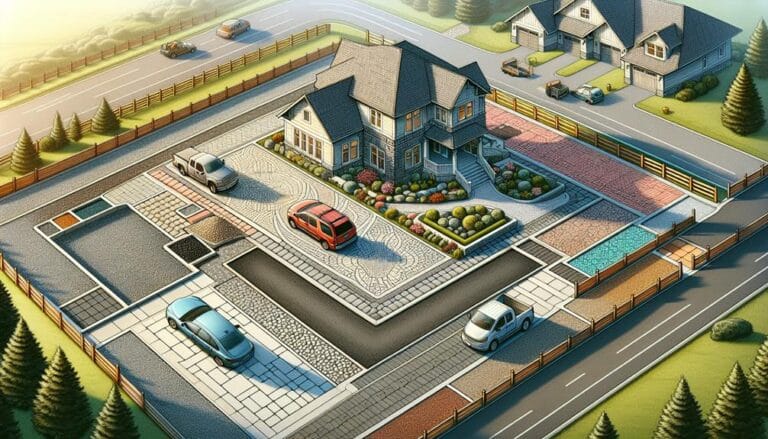

Choose Stamped or Stained Options

Now that we've discussed the importance of maintenance, let's explore stamped or stained options to enhance the aesthetic appeal of our resurfaced concrete driveway. These decorative techniques not only upgrade the visual appeal but also increase the value of your home. Stamped concrete driveways are particularly popular due to their versatility and cost-effectiveness. They can mimic the appearance of natural materials like slate or flagstone, offering a wide range of design aesthetics and color variations. By incorporating different patterns and textures, we can create a unique and visually appealing driveway that complements the style of your home.

Stamped concrete driveways are achieved by applying a pattern to the concrete surface before it sets, creating the illusion of natural material. This method is not only accessible but also allows for a high level of customization, making it easy to match the driveway's style to your home's exterior. Additionally, stamped concrete is relatively low maintenance compared to other natural materials, ensuring long-term durability without sacrificing aesthetic appeal. By opting for a stamped or stained finish, we can transform the appearance of our driveway and enhance the overall curb appeal of our property.

Consider Permit and Regulations

As concrete driveway resurfacing contractors, we emphasize the importance of obtaining the necessary permits and complying with local regulations before starting any project. Confirming compliance prevents costly delays and potential legal issues.

How do we guarantee compliance with local regulations and obtain necessary permits before commencing the resurfacing project? Here are a few key steps we take:

- Understand Permit Requirements: We familiarize ourselves with local zoning laws and permit requirements to confirm we meet all the necessary standards.

- Consult Local Authorities: We consult with local authorities to clarify any specific regulations or requirements that may apply to our project.

Review Warranties and Guarantees

To guarantee a successful concrete driveway resurfacing project, it's crucial to review warranties and guarantees provided by the contractor, guaranteeing protection against defects and poor workmanship. Before signing anything, make sure you understand the coverage and terms included.

Review the warranty to find out what's covered, such as material defects or labor issues, and for how long the protection lasts. Look for specific guarantees addressing the duration of the new surface, and check if there are any conditions or actions that void the warranty. Knowing these terms will give you peace of mind and protect your investment in case anything goes wrong.

Take note of the process for reporting any issues and the timeframe for resolving them. Verify the warranty includes a clear description of the resolution process should problems arise. By doing your due diligence now, you'll avoid potential headaches down the road. Buyer beware, so thoroughly review those warranties and guarantees before finalizing the deal. This will give you a solid foundation for a stress-free concrete driveway resurfacing experience.

Frequently Asked Questions

Can I Resurface My Driveway if It Has Deep Cracks?

"We should assess the cracks: if they're less than quarter-inch, we can fill and resurface; deeper cracks might require more extensive repairs or even replacement. Proper surface preparation is vital for a successful resurfacing."

Do I Need to Seal the Driveway After Resurfacing?

We always recommend sealing the driveway after resurfacing as part of regular driveway maintenance, as it enhances durability and protection from the elements, thereby extending the driveway's lifespan and preventing further cracks.

Will Resurfacing Hide Existing Surface Stains?

Resurfacing concrete can improve the overall look and functionality of the driveway. Before resurfacing, we confirm thorough surface preparation and stain removal to guarantee a strong bond between the existing surface and the new overlay.

Is Resurfacing a Diy-Friendly Project?

Yes, we can resurface our driveway ourselves. The process requires the right tools and thorough preparation steps, ensuring a smooth application and long-lasting results.

What Color Options Are Available for a Resurfaced Driveway?

When we resurface a driveway, choosing the right color and design is thrilling As we browse options, we can select from ten distinct colors or incorporate unique design patterns to match our home's aesthetic perfectly.